- 健康)状况:

-

New, New

- Warranty:

-

1年

- After-sales Service Provided:

-

现场安装,调试和培训

- Place of Origin:

-

中国福建

- 品牌:

-

Geili机械

- Dimension(L*W*H):

-

Accroding

- Power(W):

-

depends on machine

- 适用的行业:

-

Manufacturing Plant, Construction works

- Voltage:

-

多变的

- Weight:

-

Customized Dimension

- 认证:

-

ISO 9001:2015

- Application:

-

steel casting industry

- Radius(M):

-

R4 - R8

- Casting Type:

-

正方形(100 x 100)

- 钢铁类型:

-

Carbon steel, Bearing steel, Low alloy steel, Stainless steel

- 年产量(吨):

-

> 5k

- 工作时间:

-

20小时

Production Description

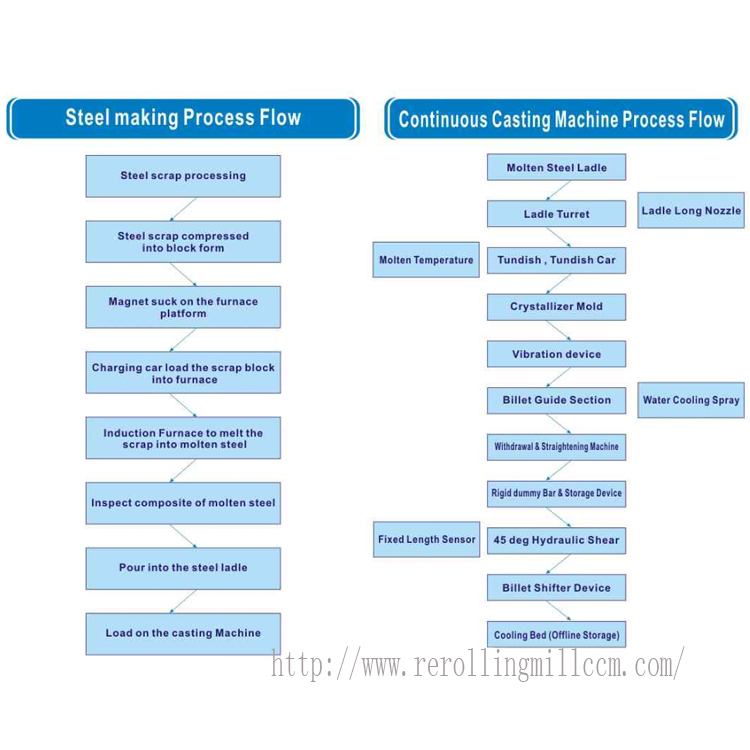

Continuous casting is a new energy-saving technique to casting the molten steel to a section shape or a certain size billet continuously and continuous casting machine is the equipment to complete this process. It includes pouring equipment, major equipment, cutting area equipment, dummy bar collection and transmission equipment. We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing.

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO。,,有限公司

wasfounded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.在2001年,与Xianyou Bangtou Mill卷制造商合并.在2008,我们focused on continuous casting and rolling production line equipment.在2011年,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD,which参与冶金设备,mainly in steel-making,continuous casting and完全的滚动生产线研发,设计,manufacturing,安装and general contracting services.

Main products:所有kinds of specifications continuous casting机器, rolling production line equipment and various辅助的equipment,also the spare parts.Besides,weprovidetechnical consultant,turnkey solution and one-stop service forsteel plant ofdeformedrebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from30,000 tons to over800000吨,滚动速度3m/s90小姐.

Customer Requirement |

容量,电力,土地等 |

解决方案讨论 |

Technical and design discussion; Most suitable proposal. |

初期 |

Provide plan layout diagram; Provide quotation machinery list. |

Detail Check & Confirm |

On-site inspection & verification; Both parties more details discussion. |

Contract Confirmation |

Final price, supply scope, terms & conditions etc. |

支付 |

Pay advance payment into the sellers's account; Issue original irrevovable L/C. |

Equipment Production |

Design and manufacture according to the supply list and equipment parameters in the contract. |

运输运输 |

在指定时间交付; Provide equipment shipping list and customer declaration data. |

Site Construction |

设备基金会; 监督完整的植物工程; Installation. |

Equipment Commissioning |

安装后进行冷命令和热调试。 |

Final Acceptance |

Buyer's final acceptance of equipment; 供应商提供的培训。 |

Perfect Service |

24-hour after-sales service; Provide spare parts purchasing and matainance service technical support. |

Quality Control:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performedservice adheres to a defined set of quality criteria or meets therequirements of the client or customer.

Finish Product QC

确保所有维度和技术过程都是正确的

绘制QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping