- 健康)状况:

-

新的

- 起源地;原产地:

-

中国福建

- 品牌:

-

盖利

- Voltage:

-

380 v

- Weight:

-

53 t

- 认证:

-

ISO 9001:2015, ISO9001:2015

- Type:

-

热滚厂

- Dimension(L*W*H):

-

2000*650*1890 mm

- Power(W):

-

1000 W

- 适用的行业:

-

制造工厂

- Key Selling Points:

-

自动的

- After Warranty Service:

-

Field maintenance and repair service

- 本地服务位置:

-

Viet Nam

- 陈列室位置:

-

Egypt, Viet Nam, Philippines, Indonesia, Thailand

- After-sales Service Provided:

-

在海外服务机械的工程师

- Product name:

-

钢滚动机钢筋带有两卷磨机

- 材料:

-

钢

- Application:

-

钢Industry

- 速度:

-

8-80 m/min

- 输出大小:

-

D3-40毫米

- 交货时间:

-

60 D

- 完成品:

-

Deformed bar

- Advantages:

-

完全自动

- Warranty:

-

1年

产品描述

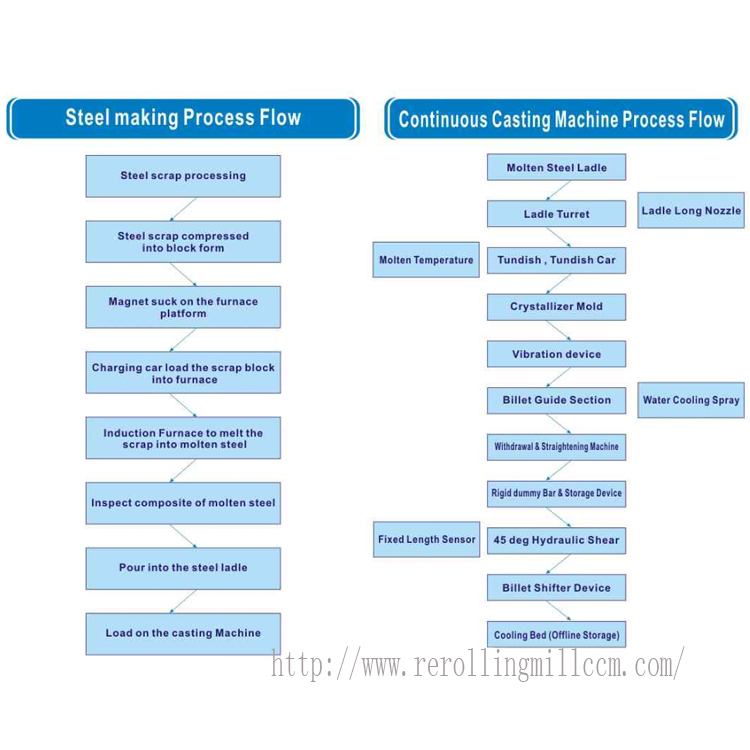

Rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce sheets or bars of a required cross section and form.

We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling bed and packing. Our hot rolling mill can produce 8-32mm deformed rebar, round bar, also wire rod.

技术参数:

生产能力:50,000公吨- 800,000公吨/year

Type of steel: quality carbon steel, low alloy steel etc.

材料:方坯尺寸从80mm x 80mm到150毫米x150mm

Final products: Φ5.5-Φ12mm wire rod, Φ8- φ40毫米钢筋

成分:

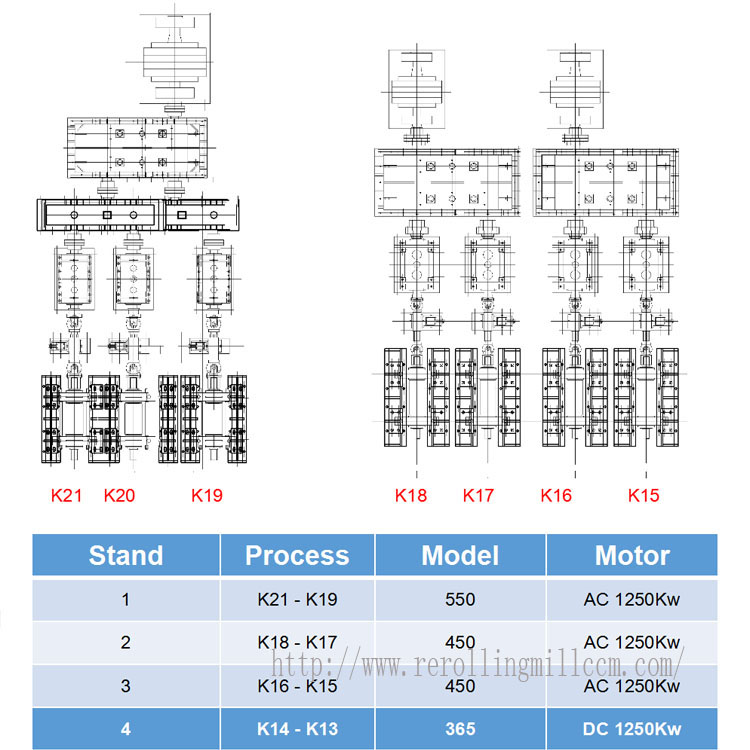

米尔站

Roller

滚子轴承

Rack

铁路支撑

滚动调整设备

Upper roll balancing device

Transmission device

Auxilliary equipment

Rolling Mill Process:

加热炉-------出来炉/CCM ----------------------------------------------------------------------------------------------------------------------------------------------------------------

前卷-------制成产品-------包装

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO。,,有限公司

wasfounded in 1995,formerly known as Xianyou Rolling Mill Manufacturer.在2001年,与Xianyou Bangtou Mill卷制造商合并.在2008,我们专注于连续铸造和滚动生产线设备.在2011年,the company reorganized and established FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO.,LTD,which参与冶金设备,mainly in steel-making,连续铸造和完全的滚动生产线研发,设计,manufacturing,安装and general contracting services.

Main products:所有kinds of specifications continuous casting机器, rolling production line equipment and various辅助的equipment,还有备件.Besides,we提供technical consultant,turnkey solution and one-stop service forsteel plant of变形rebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from30,000 tons to over800000吨,滚动速度3m/s90小姐.

Packing & Shipping

我们的服务

1)根据客户的投资和容量需求,提供最佳解决方案和合理价格的提案

2)Providing turn-key service of site planning, machinery designing, manufacturing, installation and commissioning for the full

生产线以满足客户需求。

3)Technical support. We will arrange engineers on site to install and debug the production lines until the final products are meet to customers' require

4)Perfect after-sales with long-term technical support, such as after-sales adjust the production line, develop new products or improve the equipment

Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performedservice adheres to a defined set of quality criteria or meets therequirements of the client or customer.

Finish Product QC

确保所有维度和技术过程都是正确的

绘制QC

Ensure all the drawing are inspected by Profesional Enginners

运输QC

确保产品传递给客户是最佳和正确的数量。