- Place of Origin:

-

中国福建

- 品牌:

-

Geili机械

- Bar type:

-

钢筋,圆形,正方形等。

- product size:

-

3mm ~ 36mm / 4 X4 mm - 16 X 16 mm

- 认证:

-

ISO9001:2008

- Dimension:

-

定制

- Type:

-

Fully Automatic

- 用法:

-

Base For the Cooling Bed

- Application:

-

钢

- 颜色:

-

定制

- 材料:

-

钢Material

- Function:

-

Conveyor

- After-sales Service Provided:

-

Engineers available to service machinery overseas

Product Description

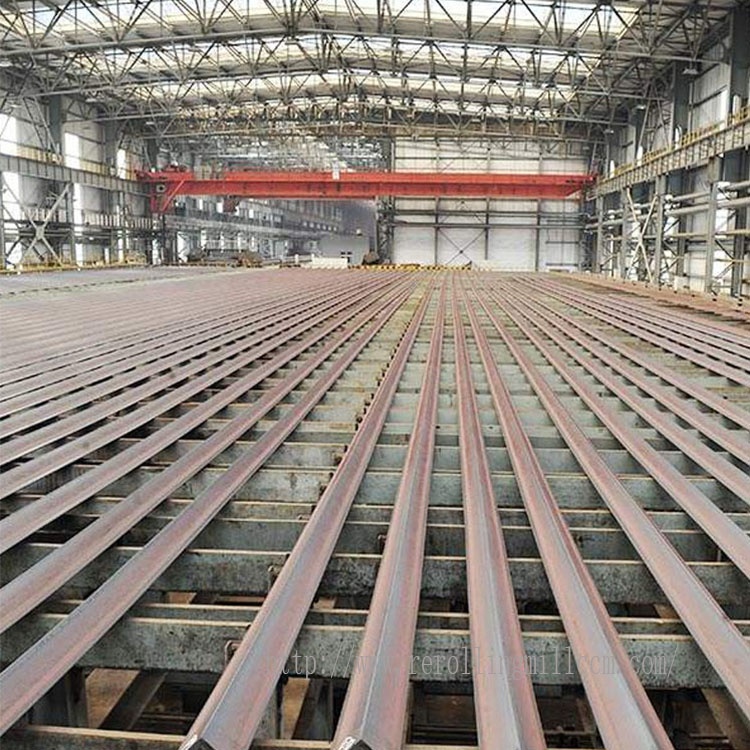

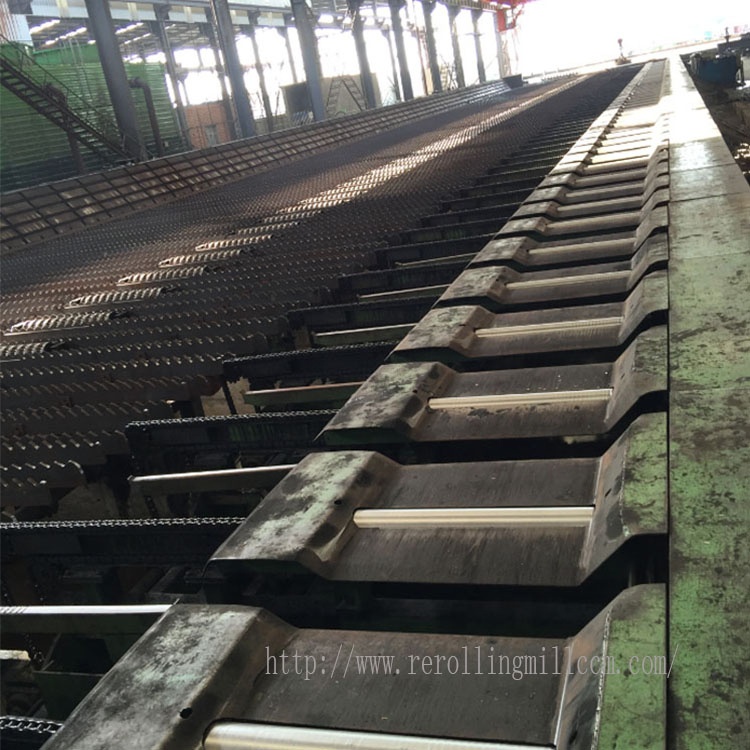

钢Rolling Mill Equipment Automatic Walking Beam Cooling Bed

冷却床是钢滚动领域的重要设备。它过去用于接收,传输和冷却滚动的零件。大小或降低后,管道的温度通常高于700°C。必须将其冷却至150°C以下,以进行后续的整理过程。管道冷却通常在冷却床上进行。

Main parts

冷却床包括机械驱动系统,水冷却系统,工作表面和固定支撑等。

优势

(1) simple structure;

(2) low investment;

(3) easy operation.

Composition:冷却床由机械传输系统,水冷却系统,冷却床工作台组成and fixed support.

工作原则: The finished products are delivered to cooling bed via conveying roller table, and then extracted by therack step by step, being pushed to the top of cooling bed, to achieve the effect of cooling rolled piece.

主要应用程序:冷却床设备主要用于自然缓慢的在线冷却滚动钢板。在里面轮廓生产线,冷却床也具有防止弯曲的功能,以防止轮廓不规则曲线through the process of natural cooling due to various quality problems. Areas of application: mainly used in steel industry,冶金工业,钢筋生产线,圆形生产线,管道生产线等。

Company Information

FUJIAN PUTIAN GEILI MACHINERY MANUFACTURING CO。,,有限公司

Main products:所有kinds of specifications continuous casting机器, rolling production line equipment and various辅助的equipment,also the spare parts.Besides,we提供technical consultant,turnkey solution and one-stop service forsteel plant ofdeformedrebar , wire rod , angle bar, channel beam, strip and other steel related production line. The Solution was based on the customer request, such as annual capacity from30,000 tons to over800000吨,滚动速度3m/s90小姐.

Cambodia( CHINA STEEL Co, LTD )Project

年度容量为300,000吨变形的钢筋线杆生产线

1. Steel Scrap Storage Area

2.中间频率炉

3.Continuous Casting Machine

4. Billet Reheating Induction Furnace

5.Continuous Roughing Mil

l6. #1 Flying Shear

7.双通道中间磨机

8.#2飞行剪切9。变形的钢筋装饰磨机

9.Deformed Rebar Finishing Mill

10. TMT Quenching Box

11.43 Flying Shear

12.机架类型冷却床

13.完成产品剪切1

4. Deformed Rebar Collection Packing Platform

15.润滑站

16. Wire Rod Finishing Mill

17. Laying Head

18. Scattered Cooling Table Roller

19. Wire Rod Collection Packing Platform

20. Water Reservoir for CC M

21. Water Reservoir for Rolling Mill

22. High Voltage Transformer Room

23. Finishing Product Storage Area

24. Electrical Control Room

Pre-sales Service After-sales Service

查询和咨询支持。培训如何安装机器,培训如何使用themachine

Proposal and initial drawingt Engineers available to service machinery overseas

View our Factory

1) Providing professional proposal of suitable production line as per customers' invest and capacity requirement

2)为整个生产线提供设计,制造,安装和调试的交钥匙服务,以满足客户的需求

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers' own request.

5)将提供良好的售后服务。如果您想调整生产线,开发新产品或改进设备,将提供我们的长期技术服务。

6) Quality warranty will be promised.

质量控制:

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performedservice adheres to a defined set of quality criteria or meets therequirements of the client or customer.

Finish Product QC

确保所有维度和技术过程都是正确的

绘制QC

Ensure all the drawing are inspected by Profesional Enginners

Shipping QC

Ensure the product pass to customer are optimum and correct quantity.

Packing & Shipping