- 起源地;原产地:

-

Fujian, China

- Brand Name:

-

GEILI MACHINERY

- 栏类型:

-

Rebar, Round, Square , etc....

- 产品尺寸:

-

3mm〜36mm / 4 x4毫米-16 x 16毫米

- Certification:

-

ISO9001:2008

- 方面:

-

Customize

- 类型:

-

全自动

- Usage:

-

冷却床的基础

- 应用:

-

Steel

- Color:

-

Customzied

- Material:

-

钢材材料

- 功能:

-

输送带

- 提供的售后服务:

-

在海外服务机械的工程师

产品描述

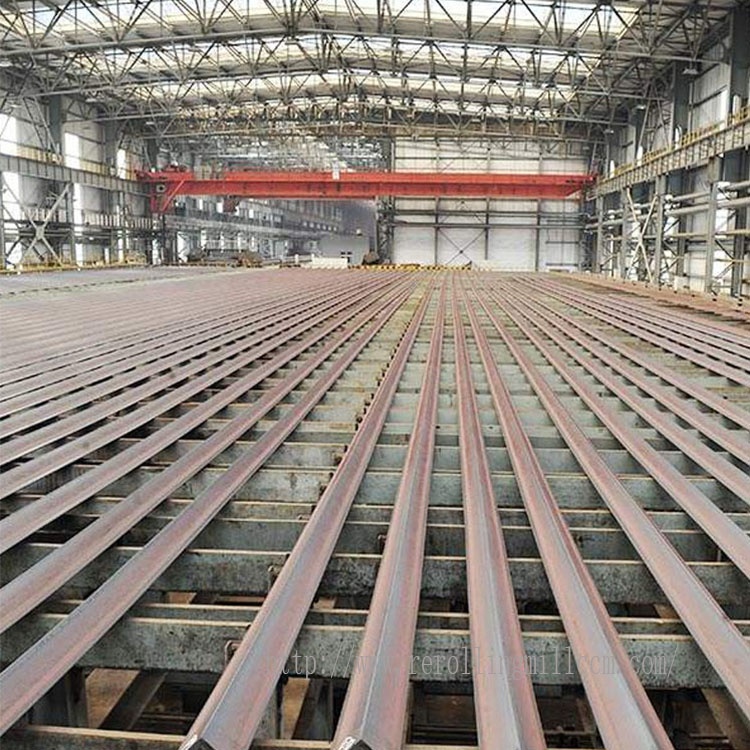

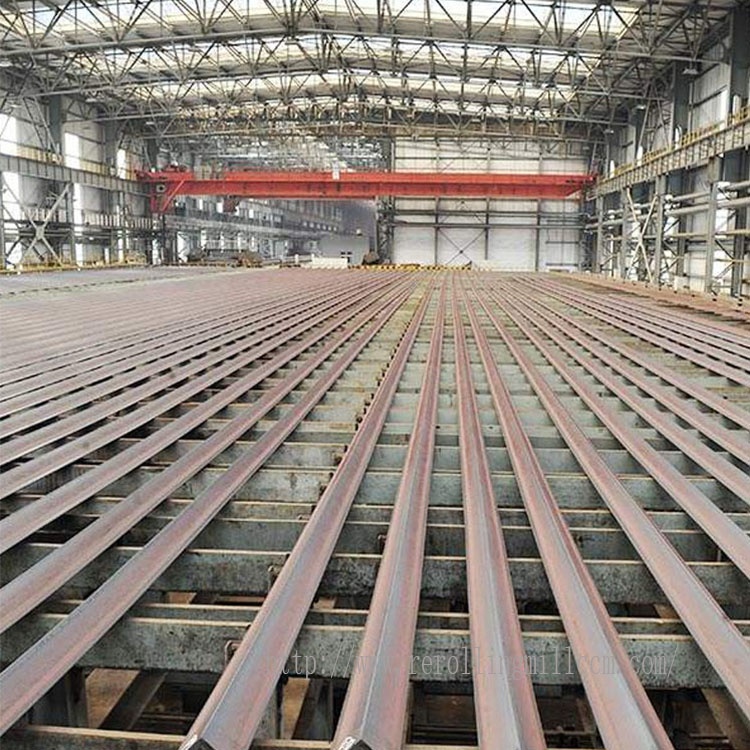

钢制滚动厂设备自动步行梁冷却床

Cooling bed is an important equipment in the field of steel rolling. It used to receiving, transmissing and cooling the rolled piece. After sizing or reducing , the temperature of pipe is generally above 700 °C. It must be cooled to below 150 °C for subsequent finishing process. The pipe cooling is usually carried out on cooling bed.

主要部分

Cooling bed include mechanical drive system, water cooling system, work surface and fixed support and so on.

优势

(1)简单结构;

(2)投资低;

(3)轻松操作。

作品:Cooling bed consist of mechanical transmission system, water cooling system, cooling bed working table和固定支持。

Working principle:最终产品通过运输辊桌传递到冷却床,然后由逐步架子,被推到冷却床的顶部,以达到冷却卷的效果。

Main application: The cooling bed equipment is mainly used for naturally slow on-line cooling of rolled steel plate. In theprofile production line, cooling bed also has the function of preventing bending, to prevent irregular curve of profiles通过自然冷却的过程,由于各种质量问题。应用领域:主要用于钢铁工业,metallurgical industry, rebar production line, round production line, pipe production line, etc.

公司信息

Fujian Putian Geili机械制造公司。,,,,LTD

主要产品:各种规格连续铸造machines,滚动生产线设备和各种auxiliary设备,还有备件。除了,我们提供技术顾问,交钥匙解决方案和一站式服务钢厂的变形回覆条,金属丝杆,角杆,通道梁,带和其他相关生产线。该解决方案基于客户reqUest,例如年度容量30,000吨800,000吨,从3m/s to90m/s。

柬埔寨(中国钢铁有限公司)项目

Annual Capacity of 300,000 Tons of Deformed Rebar Wire Rod Production Line

1.钢废品存储区

2. Intermediate Frequency Furnace

3.连续铸造机

4.钢坯加热感应炉

5.连续的粗糙mil

L6。#1飞行剪

7. Dual Channel Intermediate Mill

8。#2 Flying Shear9. Deformed Rebar Finishing Mill

9.形成的钢筋整理厂

10. TMT淬火框

11.43飞行剪

12. Rack Type Cooling Bed

13. Finishing Products Shear1

4.变形的钢筋收集包装平台

15. Lubrication Station

16.金属丝网修饰厂

17.铺设头

18.散落的冷却台辊

19.金属丝杆收集包装平台

20. CC M的水库

21.滚动厂的水库

22.高压变压室

23.整理产品存储区域

24.电气控制室

预售后售后服务

Inquiry and consulting support. Training how to instal the machine, training how to use themachine

提案和最初的绘图工程师可用于海外服务机械

查看我们的工厂

1)根据客户的投资和容量需求,提供合适生产线的专业建议

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3)为您的工厂提供基础布局和布置图

4)提供技术支持。我们将派遣各种技术人员到该网站,直到最终产品满足客户的要求为止。

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6)将承诺质量保修。

质量控制:

质量控制(QC)是旨在确保制造产品或执行的程序或一组程序服务遵守定义的一组质量标准或满足客户或客户的要求。

完成产品QC

Ensure all the dimension and technical process are correct

Drawing QC

确保所有图纸都由专业工程师检查

运输QC

确保产品传递给客户是最佳和正确的数量。

包装和运输